Hager History

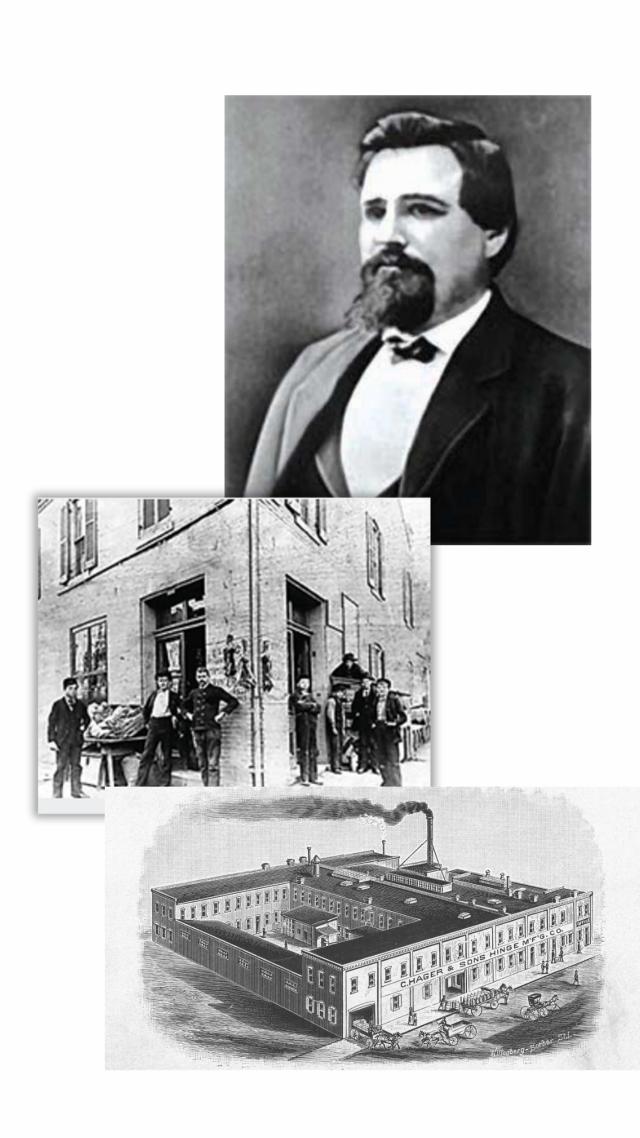

Charles Hager left Germany in 1848 and made his way to New Orleans by sailing vessel. He then traveled to St. Louis by wagon and quickly began work for a blacksmith. Only a year later, the blacksmith headed west for the gold rush and Charles bought the shop. He realized that his training as a blacksmith and wheelwright would put him in good stead as the flood of Easterners poured through St. Louis, headed west. He was right. The onslaught of gold seekers and settlers came, and Charles Hager forged wheel rims and hardware for their Conestoga wagons. He hammered out his old worn out files into knives that were used by fur traders and mountain men. His business grew, and the skill and quality he built into his hardware also built his reputation. As St. Louis grew, so did the company that bore his name: C. Hager.

By 1878, the blacksmith shop had taken on a new look and a new name: C. Hager and Sons Hinge Manufacturing Company. It was a family business now, a growing enterprise that was specializing in the manufacture of quality hardware. In 1894, Hager began producing hinges for wooden beer cases for a brand new St. Louis beer: Budweiser. The Anheuser-Busch brewery is a neighbor of Hager still to this day.

Charles Hager’s focus on quality products and unmatched customer service, coupled with a lot of hard work, gave his company a foot up on the rung of success from the very beginning. As the 1800s drew to a close, he began to pine for more. He dreamt of an expanded product line and of machinery that would make for a more efficient process. The idea of product development was forming.

In the early 1900s, Charles Hager stepped down from presidency, and his son, August W. Hager, became the company’s 2nd president. It was during this time that the country saw rapid growth of both farm and residential construction. When August W. Hager stepped into leadership, most hinges were produced by hand forging and other manual procedures. August wanted faster methods of manufacturing and, as a leader in the new industrial revolution, designed and built new machinery for the plants to meet the demands of the new century. These new techniques enabled C. Hager and Sons Hinge Manufacturing Company to increase the diversity of its products for both rural and city dwellings.

The initiation of the Panama Canal Project by President Teddy Roosevelt further enhanced business as Hager was contracted to produce massive quantities of custom hinges for locks on the canal. Then, from 1914 to 1918, during WWI, government orders for hinges continued to flourish and keep the Hager factory producing at maximum capacity.

In 1929, August W. Hager passed away, and Charles A. Hager (another son of Charles Hager) became the company’s 3rd president.

During the 1930s, the world experienced the Great Depression. As quoted from family archives by J. Withnell Hager, “We kept our organization together. We never closed. We worked half days instead of full days in order to give our employees some work. We kept going in spite of the fact that we were losing money. We stocked our inventories and kept our complete workforce intact. Hager employees have always been part of the family.”

During Charles A. Hager’s presidency, C. Hager and Sons Hinge Manufacturing Company’s sales tripled, and the company’s market share was significantly increased by the decision to sell through distributors.

In 1943, Charles A. Hager passed away, and Richard G. Hager (another son of Charles Hager) became the company’s 4th president.

In 1945, after Richard G. Hager’s death, Archer L. Hager (Charles A. Hager’s son) became the company’s 5th president. Archer had started with Hager as a shipping clerk in 1912 when he was 18 years old. While working his way to presidency, Archer operated every piece of machinery in every department of the company.

It appeared as though nothing could keep the Hager men from the company business. But, at the start of WWII, Uncle Sam called them away. C. Hager and Sons Hinge Manufacturing Company remained in business, producing hinges for the military and being run by the Hager women.

Post-WWII, under Archer’s continued leadership, Hager took the next step and moved into manufacturing and production of commercial hinges. A new catalog was produced to feature the new Architectural Hinges product line. The company also modernized its factories.

In 1970, Archer L. Hager passed away and his son, A. William Hager, became the company’s 6th president. It was under Bill’s leadership that Hager relocated its manufacturing from St. Louis to new, modern facilities in Greenville, Mississippi, and Montgomery and Oxford, Alabama. This strategic move allowed Hager to streamline production with increased capacity and state-of-the-art machinery and processes. This positioned Hager well for the company’s growth in the mid to late 1980s.

In 1985, Bill became Chairman of the Board and his eldest son, August W. “Rusty” Hager III, became the company’s 7th president. Bill later retired in 1988 and passed in 2012.

Rusty’s leadership for the remainder of the 1980s led the company to experience rapid growth. In the late 1980s, Hager expanded its product line to include Roton® continuous geared hinges, trim & auxiliary, and thresholds & weatherstripping products. In the 1990s, Hager added sliding door hardware to its product range. Rusty effectively prepared the company for the coming new millennium.

The 2000s began with the introduction of Hager’s stainless steel continuous hinges and the welcoming of the first 6th generation Hager, Josh Hager (Arch Hager’s son), to its team. Josh began his career at Hager Companies by moving to Hong Kong, China, and managing Hager’s residential hinge joint venture, handling sourcing of products, and working with international sales and marketing. In 2003, Hager Companies transitioned presidency from Rusty Hager to Charlie Hager (Rusty’s cousin), making Charlie the company’s 8th president.

2004, Josh Hager returned to the States and quickly settled in at our corporate office, taking leadership of our sourcing group and later adding purchasing and both international and domestic sales and marketing to his list of responsibilities. That same year, Hager launched locks, door controls, and exit devices. The addition of these product categories significantly broadened our product offering and enabled Hager Companies to better compete within the specification market.

In 2006, Hager transitioned presidency from Charlie Hager to Ralph Hager (Rusty’s brother), who had previously been serving as Vice Chairman and Executive Vice President. Ralph became the company’s 9th president and his transition was seamless as he continued to be an integral part of Hager’s success.

Under Ralph’s leadership, Hager has greatly expanded the security products offering. 2008 saw the addition of electric locks and exit devices. These products provide additional security and ease of use for our customers and have enabled Hager to offer an even broader range of door hardware. The company also launched Euroline – a product line focused on meeting the needs of our international customers. This expansion of product lines has positioned Hager Companies as a global leader. Our products can be found in buildings throughout the Middle East (including the Burj Khalifa and Burj Al Arab in Dubai) as well as Central and South America, Asia, and North America.

In 2009, Hager consolidated its Oxford and Montgomery, Alabama, manufacturing plants and opened a brand new distribution center in Phoenix, Arizona – both in an effort to manufacture and distribute products more efficiently and to better serve our customers.

In 2010, Hager welcomed its second 6th generation Hager, Johnston Hager (Ralph Hager’s son) to our team. Johnston started out as Product Manager for architectural hinges and thresholds & weatherstripping.

In 2012, Hager welcomed its third 6th generation Hager, August Hager (Rusty’s son) to the team. August started out as an Architectural Specification Associate. August became the first Hager to obtain his Architectural Hardware Consultant (AHC) through the Door & Hardware Institute (DHI). Following this achievement, he wrote Specifications for many years.

Also in 2012, Hager launched a line of electrified products, including electric strikes, keypads, and magnetic locks.

In 2013, Hager added a new line of low energy power operators and actuators. The 8400 Series Low Energy Power Operator is an ideal solution to meet ADA while eliminating noise in sensitive areas making it a perfect fit for hospitals, libraries, and senior care facilities.

In 2015, Hager introduced the Hager H family of keyways. Hager’s Keyway allowed the use of one single key to support the expanding product lines including conventional products and European lines. Hager also added the 2300 Series deco leverset to its Locks Product Category. Continuing his growth within the company, Johnston Hager was promoted to Director of Residential Sales.

In 2016, Hager launched the large format interchangeable cores to work in conjunction with the Grade 1 cylindrical leversets, mortise locks, and exit device trims. Additional products were added to our trim & auxiliary product line including the 334V door knocker with viewer and diamond pattern flat goods. Keeping safety at the forefront Hager added a photoluminescent push bar cover option, an optional flush end cap, and anti-vandal pulls to the exit device product category. Hager also added the 9400 Series stainless steel sliding door hardware to the sliding door product line.

In 2017, Hager announced their alliance with Salto Systems, Hager powered by Salto, creating a new product category for electronic access control. The HS4 platforms provide solutions for the entire building and adapts easily to evolving requirements and budgets for a multitude of vertical markets including multi-family, assisted living, education, and healthcare. Additionally, Hager introduced the 34K standalone lock and the quick connect ETW to the electronic product line.

2017 also brought changes to the leadership at Hager. Josh Hager was promoted to the position of president and chief operating officer and Johnston Hager was promoted to vice president of residential sales and national accounts.

In 2018, Hager introduced additional products across several product categories including: 3300 Series Grade 3 leversets to the lock product line; hospitality transitional thresholds to our threshold and weatherstripping product line; the new sliding barn door privacy lock and the door cushion stop to the sliding door hardware product line, new power supplies and door prop alarms to the electronic product line, the eConestoga economical sliding door hardware, and BLUEnet, Interconnected GEO, KS Platform, and the AElement to the HS4 electronic access control product line.

In 2019, new safety features for our Roton® Continuous Geared Hinges were launched with the release of the TIPIT® Ligature-Resistant Hospital Tip and a newly improved Hospital Tip. The 8300 Series was added to the low energy power operator family to provide ADA compliance to both interior and exterior door openings.

Hager celebrated its 170- year anniversary and received the 2019 St. Louis Business Journal Family Business Award. Besides Josh, Johnston, and August Hager, this year brought the newest sixth-generation family member, Warren “Sonny” Hager Jr., who began his in-house training. August Hager IV was promoted to strategic account executive.

The company began modernizing and expanding its manufacturing and warehouse operations in late 2019 with a $20 million investment. An existing warehouse in Montgomery is being replaced with a new distribution center and state-of-the-art Automated Storage and Retrieval System (ASRS).

The beginning of 2020 brought changes to Hager leadership responsibilities. Johnston Hager was promoted to senior vice president and added Customer Service and Technical Support to his obligations.

Hager Companies faced a new challenge in the spring of 2020, the COVID-19 pandemic. Building on the ingenuity Hager has shown during previous times of great turmoil, the company remained committed to protecting what is most important – our people, our customers, and our communities.

The timely introduction of Hager University, an online educational tool to learn about Hager’s products and the industry, was announced in June of 2020. Modules vary in length from eight to 15 minutes with knowledge checks along the way and a short test at the end. New modules continue to be added. As noted by a valued customer, “Continuing to develop strong new talent into our industry is extremely important and programs like Hager University have a tremendous impact on our ability to teach the employees of tomorrow.”

Despite the challenges the pandemic presented, product launches continued in 2020 with the 4600 Series Concealed Vertical Rod Exit Device, the KS Mini, NEO cylinder, restroom and emergency kits, and power supplies to the electronic access control product line, and an adjustable 5400 Series to the door control line. Hager also announced the new durable powder coated DBZ finish that complies with ANSI/BHMA finish code 695, providing a stable finish for several of our Trim & Auxiliary products. With security and safety at the forefront of Hager’s product offering the 82-institution function was added to the 3400 Series Grade 1 cylindrical lock offering. Rounding out the respective product lines, the 9459 surface jamb mount privacy lock was introduced to the sliding door hardware category, as was door bottoms with flexible fins for the threshold & weatherstrip hospitality line.

The new distribution center was completed in the fall of 2020 and the transition to the new warehouse and software system began.

In 2021 the continued concern for touchless door openings to prevent the spread of germs and bacteria brought solutions for our customers. New products like the 190L foot pull were launched and promotions to support touchless openings with the 8300 Low Energy Power Operator with waveless actuator offered.

The sliding door hardware product line announced the addition of the new 9600 Commercial and 9800 Heavy-Duty Pocket Door Frame Kit Series.

Sonny Hager transitioned to the product manager for threshold and weatherstripping.

Hager also launched the new website in the summer of 2021. With a streamlined design and functionality, the new site is full of features and accessible resources.

Changes in leadership in 2022 saw Hager getting back to basics. R. Johnston Hager, III was promoted to the position of president and chief operating officer. In his role as senior vice president of residential sales, national accounts and customer support, Johnston was instrumental in driving customer relationships and reorganizing Hager’s customer support team. Under his leadership, Hager was able to increase market share in our residential products category during the post-pandemic supply chain struggles. “I am pleased with the direction our company is going and expect continued success with Johnston leading our team as President and Chief Operating Officer”, said C.E.O. Ralph Hager. “On behalf of the board of directors and the entire Hager team, I want to congratulate Johnston on his promotion and wish him the best in his new role. I have complete faith in his abilities to lead our team to continued top and bottom-line growth going forward.”

August Hager IV, A.H.C. is also expanding his role and taking on additional responsibility as sales manager for Hager’s Southeast region. August’s customer acumen, product knowledge, industry experience, and leadership will help support Hager’s sales initiative of returning to the basics and being more engaged with our field sales organization and valued customers. August remains Vice President of Technical Services and will leverage information ascertained in the field to continue expanding internal support for all of Hager’s global customers.