General Product Maintenance

DOWNLOAD GENERAL DOOR HARDWARE CARE INFORMATION HERE

FINISHES

Hager Companies finishes are durable, high quality finishes obtained by the careful processing of steel, brass, bronze, stainless steel, zinc or other materials. Where required, a protective clear coating is applied and cured under high temperature. It is important to consider usage and climatic conditions when selecting finishes. This is especially true in areas subjected to strong corrosive chemical conditions, humid climate or salt air, which may have a damaging effect on metal finishes in a short period of time.

The longevity and preservation of the finish appearance is determined by base metal and finishing process. Care and maintenance of clear protective coating or other organic finishing applications may require different methods of cleaning and care. As an example, non-clear coated finishes should not be cleaned with soaps or any solvents or abrasives; organically coated surfaces should periodically be cleaned with a mild non-abrasive soap and buffed lightly with a clean cloth. The type of base metal and finishing techniques must be considered when applying any cleaning or preservative method.

The following are the recommended methods for cleaning popular finishes.

-

- Satin stainless steel: Use a non-chlorinated kitchen or stainless steel cleaner and a soft cloth. Any cleaner safe for glass is usually safe for stainless steel. Light surface rust can readily be removed by rubbing the surface with a brass silver or chrome cleaner. Irreversible pitting will develop under rust that remains on stainless for any period of time. Never clean with mineral acids or bleaches. For added protection apply a coat of good car wax.

- Polished stainless steel: Same as above.

- Lacquered brass and bronze: Use a soft cloth and mild soap and water. Never use brass polish or abrasive cleaners unless you are totally refinishing the product.

- Un-lacquered brass and bronze: Use a soft cloth and a copper or brass cleaning product (such as Flitz).

- Oil rubbed bronze: Use a soft cloth and 3 in 1 oil, lemon oil, or similar light oil product. Very lightly coat the surface with oil and gently rub the surface to re-blend the finish. Do not rub too hard or you will remove the oxide coating that gives this finish it antique brown finish. It is normal for the oxide to wear off in areas of products that normally are routinely touched such as door pull grip areas.

- Chrome: Use a soft cloth and mild soap and water.

- Aluminum and brass-look aluminum: Use a soft cloth and mild soap and water.

LOCKSETS

Hager lock assemblies are designed for durability and seldom need servicing. During assembly, those points of contact which require lubrication for ease of operation are given an application of high quality lithium grease. A touch of graphite is applied to the pin tumbler plug during assembly of the cylinder unit. Periodically inspect latch, strike and spring cage screws for tightness. No further servicing should be required for an extended period except where locks are subjected to extremely heavy traffic. Also, if located in particularly dusty or dirty areas, the grease may become contaminated resulting in a slow or otherwise unsatisfactory operation. The case mechanism should then be cleaned in noncorrosive petroleum solvent and re-lubricated with high quality lithium grease. Graphite only should be applied to the cylinder unit by blowing a small quantity into the keyway. WD40 is not recommended for lubricating the cylinder unit as the oil base used is too light and will not carry the metal filings and dust away, causing the pins to possibly clog.

EXIT DEVICES

Exit Devices are designed for life safety first. Hager Companies devices are cycle tested, both as prototypes during design and as quality samples during production. Hager Companies exit devices are designed and built to be maintenance free; however, such factors as installation, severity of use, environmental conditions, and changes in the condition of the door opening may require that maintenance and/or device adjustment be performed. The following guidelines are recommended to the building owner to insure proper device operation:

Check device operation for smooth operation periodically.

-

- Check strikes and latches to insure they are secure.

- Check latches and other moving parts for binding or sluggish operation due to dirt or chemical buildup. Clean parts with soap and water and then lubricate with lithium grease or silicone lubricants. Do not use

petroleum-based lubricants. - Painted finishes are not recommended for high traffic applications where appearance is of upmost importance.

- The appearance of fine scratches on some finishes can be minimized with a thin coating of good car wax.

Periodic adjustments to exit device rods may be required to compensate for door or frame sag. Service personnel should be reminded that life safety is the goal.

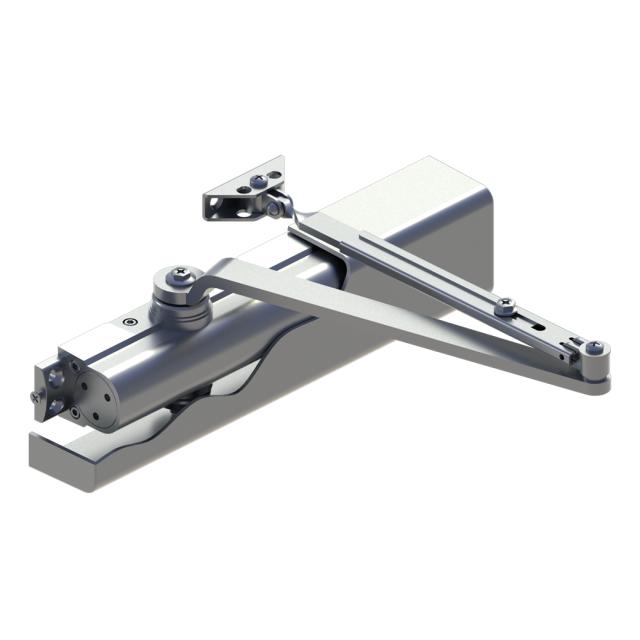

CLOSERS

Periodic adjustments to closers are not necessary, however the closers can be adjusted to best accommodate different circumstances (see product data). Periodically lubricate the pivot points on closer arms with a small amount of silicone base lubricant to ensure smooth operation and long life.

ARCHITECTURAL AND RESIDENTIAL HINGES

- Hinges must be free swinging without any binding. The use of shims to align hinges, if required, is satisfactory.

- Hinges should be well greased and checked on a regular basis for lubrication. We recommend that hinges used in commercial, high-frequency applications or those in extreme environmental conditions be lubricated annually to ensure quiet operation and long life.

- Standard hinges are best lubricated by removing the pin, applying a generous coating of lithium grease, and reinserting the pin by driving it completely down to the shoulder of the pin head. Light oils such as WD40 are not recommended as they dry quickly and wear away over a short period of time.

- Hospital Tip (HT) hinges that have fixed hinge pins have an oil port on the knuckle for the purpose of lubrication. The hinge knuckle is designed with a .107 diameter lubrication port set at 15 degrees off the leaf, making it accessible when the door is opened 90 degrees. Lubrication is accomplished with a standard, manual grease gun fitted with a rubber cone tip (Lincoln Rigid Adapter #83278) using white lithium grease. With the door at 90 degrees, insert the rubber tip into the lubrication port in the barrel of the hinge and pump grease until it flows from between the single and double knuckles.

- If hinges are sized properly for the door and the frequency of use, they will last for a considerable period of time.

- Steel hinges are intended for use on interior applications only. Brass and stainless steel hinges can be used for either interior or exterior applications. Paint or plated finishes over steel or brass are for decorative appearance only. All steel will eventually rust and all brass will eventually tarnish. To slow the corrosion or tarnishing process, a lacquer coating is applied between the steel or brass and the atmospheric conditions. Plated finishes receive a clear coating of lacquer.

- Hager’s painted finishes will withstand a standard salt spray test of 48 hours and plated finishes coated with clear lacquer will withstand a standard salt spray test of 24 hours. Care should be used when installing hinges to avoid damage to the paint or plated finish.

- To remove dirt, simply wipe with a soft damp cloth. Abrasive cleaners or lacquer thinner should not be used to clean the surface of hinges. To do so will void any warranty for the product.

- If hinges begin to make any noise, remove binding conditions and grease or lubricate all moving parts.

ROTON CONTINUOUS GEARED HINGES

- No additional lubrication is required.

- An occasional removal of airborne debris may be accomplished with a mild detergent. This will help maintain the appearance.

- The use of a thread locking material on all screw threads is recommended for hinges on all public buildings.

- Hinge screws should be periodically inspected for tightness in high traffic areas.

TRIM & AUXILIARY

- Abrasive cleaners or lacquer thinner should not be used to clean the surface of this product. To do so will void the warranty for the product.

- Periodically lubricate any moving parts with a silicone based or lithium grease.

- Periodically inspect screws for tightness.

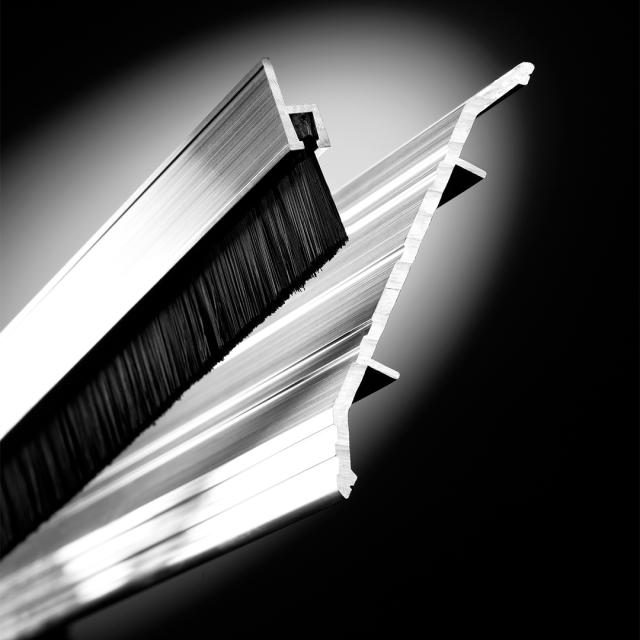

THRESHOLDS & WEATHERSTRIPPING

For threshold and weatherstripping a visual and operational inspection should be performed periodically.

- Inspect for signs of deterioration such as splitting, cracking, or deforming of flexible components. Install replacement components as needed.

- Occasionally remove airborne debris from the surface and tracks by using a mild detergent and a soft damp cloth.

- Gasketing should be positioned to create proper contact along the door’s entire perimeter. Test with a common letterhead paper. The paper should be held in place by inserting it between the door and gasket, and then closing the door. If paper is not held firmly in place, the seal is inadequate. Use the paper test on the entire perimeter.

- Periodically inspect screws for tightness.